1. Corrosion mechanism in metal

-What are

conditions when corrosion starts? How you can protect metal from corrosion?

= There

are three (3) main components necessary for corrosion to occur:

-Metal (iron)

-Oxygen (usually from atmosphere)

-An electrolyte (usually water)

U can protect metal from corrosion by few ways, but most usual is

painting it. The paint forms a barrier between the metal and the environment.

2. Standards

-Durability is indicated in ISO 12944-1 in terms of

three ranges. What are these ranges?

=Low (L) 2-5 years

Medium (M) 5-15 years

High (H) over 15 years

3.

Measurements of dry film thickness

-How you do yourself measurement of dry

film?

=I haven't measured dry film myself, but u can measure it by using coating

thickness cauge (example: Elcometer)

4. Prerequisites for good corrosion protection painting , My workplace's difference to school.

-What are prerequisites for good corrosion protection

painting?

= You need

to know all information on all parameters influencing the durability of the coating, example: A cargo ship is painted with different paint thickness than an office, because an office is usually heated house and with clean atmosphere, unlike the cargo ship.

At my workplace there are bigger equipment than school so bigger tasks can be done. And there is always something to do, i have done mostly grinding and taping.

5.Painting as a design consideration for steel structures

-What kind of designs are bad for corrosion-protection?

6. Removal of grease and soil

-ISO 12944-4 STANDARD

= 1. Surface preparation using flame cleaning

At my workplace there are bigger equipment than school so bigger tasks can be done. And there is always something to do, i have done mostly grinding and taping.

5.Painting as a design consideration for steel structures

-What kind of designs are bad for corrosion-protection?

6. Removal of grease and soil

-ISO 12944-4 STANDARD

= 1. Surface preparation using flame cleaning

=2. Chemical cleaning

=3. Mechanical cleaning

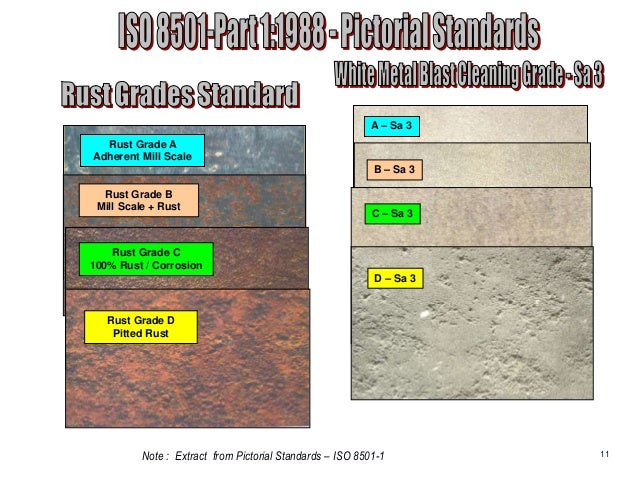

7. Rust grades

8. Medium grade after blast cleaning

Removing visible stains and rust from surface

9. Prefabrication primer treatment

=The primer must have atleast following properties

-Must dry very quickly, the primer should be capable of airless spray application to produce very thin even coating, (dry film thickness usually 15-25μm), the primer coating should provide enough protection until either overcoated or placed within a non-corrosive environment (example: indoor storage or within a building construction).

10. Etching primers

=Etching primer is used on bare metal to prevent rust problem from getting worse, remember that metal is totally cleaned so it can be fully effective, it means cleaning everything even fingerprints.

11. Composition of paints

=Basic composition of paint

-Solvents

-Pigments

-Addictives

-Resins

12. Paint types at my workplace

=Not sure that i can list all but here's some

-Electrically conductive paint to make plastic cups to conduct electricity

-Corrosion-protective paints

13. Marking of the paint systems

=SFS-EN ISO 12944 – 5/A2.02 (AK 120/2 – Fe Sa 2½)

=Painter(he) gets from this, paint is matt, he is painting iron which needs to be cleaned to Sa2.5. And there needs to be painted 2 layers of 120μm.

14. Corrosivity categories

=What is meaning of corrosivity category C5 Marine

- C5-M belongs to very high atmospheric-corrosivity category. Which means it can be used areas with high salinity (example: Coastal and offshore areas.)

15. Painting methods.

=In the determination of the painting method, the following must be considered, among others:

-Where is painted object used (at salty sea, Car)

-Finance

-Remember that painting needs to last the possible installation of the object

-Where is the object painted